Company History

1962

Sep.

Established Daiwa Koki Co., Ltd. (Capital: 1 million yen)

Oct.

Started R&D on the steel plate lifting clamps

1963

May

Relocated the head office to Tanimachi, Chuo-ku, Osaka

1964

May

Completed the prototype of the steel plate lifting clamp

Jul.

Passed the Safety Performance Test by the National Institute of Industrial Safety (NIIS), Ministry of Labor

Aug.

Applied for a utility model (the Model SL and the Model RS)

Oct.

Established the trademark “Eagle Clamp” and began product sales

1966

Feb.

Signed a product liability (PL) insurance contract with Tokio Marine & Fire Insurance Co., with coverage of 1 million yen per clamp. (First in Japan)

1969

Apr.

Signed a patent license agreement with Nippon Kokan Co., Ltd. for a multi-point suspension beam block loader

Jul.

Implemented a computer system for after-sales service management

1970

Aug.

Established Nara Plant

1971

Feb.

Signed a patent license agreement with Mitsui Engineering & Shipbuilding Co., Ltd.

(a special beam used in material handling)

1973

Jan.

Renamed the company to Eagle Clamp

Jul.

Signed a patent license agreement with Ishikawajima-Harima Heavy Industries Co., Ltd.

(a steel support suspension device)

1974

Jan.

Signed a patent license agreement with Mitsubishi Heavy Industries, Ltd.

(a plate clamping device)

Mar.

Expansion of Nara Plant

1975

Apr.

Signed a patent license agreement with Tokyu Car Corporation

(a suspension device)

1977

Jun.

President Yoshizo Tsuyama (founding president) was awarded the Medal with Dark Blue Ribbon

1978

Jul.

Upgraded the computer system, including modules for procurement, sales, and management

Dec.

Received an award for excellence in promoting invention and ingenuity

1980

Aug.

Established Eagle Tsusho Co., Ltd. as a group company

1983

Apr.

Launched the Model UGH clamp for lifting U-shaped concrete channels

1984

Apr.

Launched the Model SBB universal screw clamp

1985

Jun.

Implemented a mainframe computer system to streamline after-sales clamp and sales management operations

Jun.

The Model SL Clamp certified with GS mark in West Germany

1986

Feb.

Developed and launched the Model AMS clamp for steel erection

May

Launched the Model CDER coil lifter with a wireless control system

Jun.

Launched the Model ELC clamp for long U-shaped concrete channels

Aug.

Developed an automatic device for cam tightening and hole processing

Aug.

Launched the Model EKB clamp for concrete wedge blocks

Oct.

Launched the Model CCL and the Model CCV clamps for columns

1987

Apr.

Received the Director General's Award from the Science and Technology Agency (for the development of the automatic hole processing device, the Model ADM-40)

Apr.

Launched the Model ECC lightweight clamp for concrete products

May

Patent granted for the Model NE non-marring clamp

Jun.

Developed and launched wireless unslinging device (Mighty Shackle Ace)

1988

Apr.

Utility model granted for the Model NNE non-marring clamp

Apr.

Completed safety education and PR videos, including “Toward Zero Accidents” and five other titles

Apr.

President Yoshizo Tsuyama (founding president) was awarded the Order of the Sacred Treasure, Gold and Silver Rays

1990

Jun.

EC patent granted for the Model NEC non-marring clamp

1991

Mar.

Implemented a new NCR computer system for sales management

1992

Jul.

Expansion of Nara Plant

1993

Jul.

Utility model granted for the Model DLV drum-lifting clamp

1996

Feb.

Installed a UH-100A universal testing machine (manufactured by Shimadzu Corporation)

Jun.

Patent granted for the Model GC clamp for lifting column joints (No. 2535305)

1998

Oct.

Launched the Model EUIV clamp for internal lifting of concrete products

1999

Jun.

Patent granted for the power shackle, an automatic unslinging device

Oct.

Launched the Model BBC battery-operated portable hoist

2000

Mar.

Launched the Model EST clamp for auxiliary concrete products

Apr.

Nara Plant (Manufacturing & Technical Depts.) was certified under ISO 9001 (No. 200132)

Jun.

Established Eagle Lifting Systems Co., Ltd. as a group company

Nov.

Launched the Model UGHC clamp for concrete products

Dec.

Launched the Model ECHR clamp for wooden beams

2001

Feb.

Launched the Model BTSW clamp for stone (automatic attachment and detachment)

2002

Aug.

Launched the Model VAFS horizontal lifting clamp

Oct.

Launched the Model GT lateral lifting clamp

2003

Sep.

Expanded ISO9001 certification to include the head office and Osaka sales office

Nov.

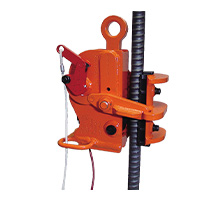

Launched the Model CSBL clamp for rebar

Nov.

Received the Director General’s Encouragement Award from the Small and Medium Enterprise Agency for developing "One-touch non-marring clamp for steel plate"

Nov.

Expanded ISO9001 certification scope to include maintenance (YKA0200132)

Dec.

Launched Model the NNEⅡL Non-marring vertical lifting clamp

2004

Apr.

Received Minister of Education Award for developing "One-touch non-marring clamp for steel plate"

2006

Apr.

Expanded ISO9001 certification to include Tokyo, Sendai, and Kokura sales offices and the Trade department

Apr.

Received Minister of Education Award for Creativity and Contribution for the development of a cam gear cutting machine

2007

May

Implemented company-wide online system for sales, administration, and product management

2008

Feb.

Capital increased to 49.5 million yen

Apr.

Chairperson Hatsuo Tsuyama was awarded the Medal with Yellow Ribbon

Apr.

Received Minister of Education Award for Creativity and Contribution for the development of proof load test equipment

2010

Apr.

Received Minister of Education Award for Creativity and Contribution for the development of a fixture for gas cutting machines

2011

May

Participated in the reactor building cover installation at Fukushima Daiichi Nuclear Power Plant

Nov.

Shinji Tsuyama became Representative Director

2012

Sep.

50th Company Anniversary

2014

Apr.

Received Minister of Education Award for Creativity and Contribution for the development of a pin marking device

2015

May

Installed laser processing equipment

Jul.

Completed new Nara plant

Jul.

Installed an automatic crimping machine

Aug.

Installed an automatic polishing machine

2016

Apr.

Chairman Hatsuo Tsuyama was awarded the Order of the Rising Sun, Gold and Silver Rays

Oct.

Launched the Model SATO hole lifting jig

2017

Jan.

Cam pin cover received the Nara Prefectural Assembly Chairman’s Award at the Nara Idea and Invention Exhibition

2018

Feb.

The Model EUIF clamp for internal concrete lifting received the Nara Design Association Prize at the Nara Idea and Invention Exhibition

Mar.

Launched the Model BHC beam hanger clamp

Aug.

Installed a machining center

Dec.

Implemented a new core system

2019

Sep.

Relocated the head office to Otemae, Chuo-ku, Osaka

Nov.

Clamp for safety harness (fall arrest equipment) received the Nara Governor’s Award at the Kinki Regional Invention Awards

2020

Oct.

Chairman Hatsuo Tsuyama was awarded the Invention Encouragement Service Award at the National Commendation for Invention

Nov.

Launched the Model SBMR clamp for horizontal lifelines

Nov.

Power cable anti-tangle device received the Director General’s Award from the Small and Medium Enterprise Agency at the Kinki Regional Invention Awards

2021

Feb.

Relocated the head office to Nakanoshima, Kita-ku, Osaka

Mar.

Expanded ISO9001 certification to all departments (YKA0200132)

Jun.

The group company Eagle Lifting Systems Co., Ltd. was renamed Aquila Co., Ltd.

Nov.

Launched the Model LV and the Model LH clamps for lightweight loads

Nov.

The coil drop prevention device for the Model C coil hook received the President’s Award from the Nara Invention Association at the Kinki Regional Invention Awards

2022

Jan.

Launched the Model ECX clamp for auxiliary concrete products

Aug.

Formed a capital alliance with Osaka Kikai Co., Ltd.

Nov.

The hazard warning device on the coil lifters received the Nara Prefectural Governor’s Award at the Kinki Regional Invention Awards

2023

Jun.

Launched the Model LHF clamp for lightweight loads

Jul.

The group company Eagle Tsusho Co., Ltd. was renamed Halcon Co., Ltd.

2024

Oct.

The Model SBB all-direction screw clamp for steel parts received the Good Design Award

Nov.

The compact coil hook on the Model CDE coil lifter received the Director General’s Award from the Small and Medium Enterprise Agency