Quality Commitment

Planning & Development

High Quality Lifting Clamps Inspired by Future Visionary Innovation

We, Eagle Clamp, are committed to placing customer needs first, with custom-made solutions at the core of our manufacturing.

For over 60 years, our dedication to multi-variety, small-lot production tailored to each customer has earned us the trust of numerous industries.

The Model CDER wireless coil lifter is a prime example of our innovative planning and development capabilities.

Moving forward, we will continue to work hand in hand with our customers, exploring new possibilities and developing lifting equipment that are safer, more efficient, and more labor-saving than ever before.

Certifications and Standards for Safety

We place the highest priority on product quality and reliability.

We continuously develop and improve our quality management system in accordance with international standards.

- JCAS

- Our products are developed and quality-controlled in accordance with the safety standards and inspection guidelines defined by the Japan Crane Association Standards (JCAS).

- EN Standards

- Our products are designed and manufactured in compliance with EN standards, the safety and quality standards in Europe.

- CE Marking

- Our products conform to European directives and standards, as verified by CE marking.

- AS Standards

- Our products are designed and manufactured in compliance with AS standards issued by Standards Australia.

Lots of Patents and Utility Models / Global Products

We are constantly exploring new fields to drive innovation.

Our extensive portfolio of domestic and international patents and utility models is proof of our ability to innovate.

Today, we continue delivering future focused solutions across diverse industries.

- Number of Intellectual Property Rights 126

-

- Number of Trademark Rights 53

- (Including 2 Foreign Intellectual Property Rights 2)

- Number of Patents 47

- Number of Utility Models 8

- Number of Design Rights 18

- Number of Invention Awards 52

- (Decorations, Minister of Education, Culture, Sports, Science and Technology Awards, Regional Invention Awards, etc.)

(As of January 2022)

Manufacturing & Product Management

At Eagle Clamp, we combine over 60 years of clamp manufacturing expertise with advanced technologies such as CAD/CAM and Factory Automation (FA) in our design, machining, and production processes.

To meet the diverse needs of our customers, we are committed to both product development and consistently high-quality manufacturing.

Eagle Product Manufacturing Process

01Planning & Design

A good understanding of customer needs and worksite situations is important for our product development.

With our wealth of technology and experience, we incorporate innovative ideas and advanced technologies unbound by conventional concepts and deliver optimal solutions.

02Manufacturing & Processing

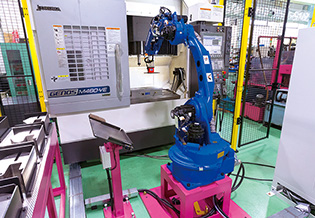

By sending design data from 3D CAD / CAM to NC processing machines and production robots for further operations, we achieve process innovation.

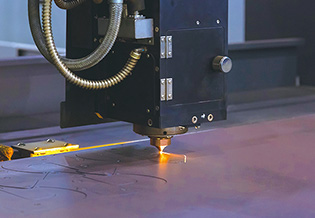

Thermal Cutting

Machining

Cutting

Assembly

03Product Inspection

Using dedicated equipment that adheres to national standards and ensures traceability, we conduct proof load-testing at 2.5 times the working load limit. We also conduct Rockwell hardness testing and destructive testing using an Amsler tensile testing machine. Through thorough and strict inspections, we maintain a high level of evidence and assurance across our entire products.

Ensuring Safety in Design and Manufacturing

Our products comply with the safety factors for slinging hooks specified in the Japanese Industrial Safety and Health Act and the Crane Safety Regulations.

Performance Test Accepted Products

Acceptance criteria is “no permanent deformation at 2.5 times the load”.

The main body is made from high-tensile steel and alloy steel with excellent strength, toughness, and workability.

The cam is made of our company's original alloy steel.

While maintaining the strength of the cam, we manufacture and process the tooth tip to achieve optimal hardness (wear resistance).

04Product Control

Product registration

An information control number is stamped on each product. We also control our products using RFID tags.

Shipping Control

Shipping dates and shipping destinations are registered for each product.

In addition, a test certificate is attached to each product.

User master registration

User information and related information is registered. This enables us to clarify the history of each product and further improve our after-sales service.

ISO Certified

ISO Certified Including the After-Sales Service Division

We, Eagle Clamp, have been dedicated to strengthening our quality management system since 1999 and obtained ISO 9001 certification in April 2000. We remain committed to continuous improvement in quality.

Eagle Clamp’s Quality Policy

- We provide safe, high-quality products and attentive services to meet customer needs.

- We deliver innovative and original ideas that exceed customer expectations.

- We develop skilled personnel and promote safer, more-efficient working environments.

- We set ambitious quality goals, pursue continuous improvement, and strive to achieve our targets.

- We comply with all applicable standards and social requirements to ensure full conformity.