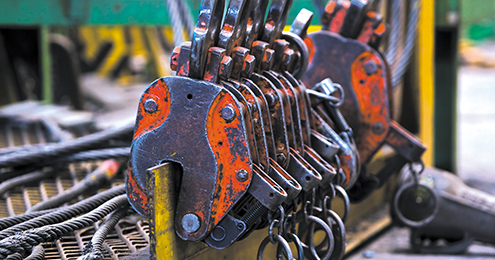

Clamp Maintenance and Inspection by Users

Maintenance Key Points

Clamp maintenance and inspection help achieve zero accidents.

Following appropriate maintenance and inspection practices improves work efficiency and achieves lower total costs by preserving clamp life.

Store indoors by application

- To prevent rust, do not leave clamps outdoors after use.

- To improve work efficiency, store clamps together by application.

Inspect and Maintain Regularly

- Be sure to inspect before operation and to maintain after operation.

- Inspect and maintain regularly, even if the clamp is not used (around once a month).

- When inspecting or maintaining, apply oil to the sliding parts.

Never Use Damaged or Deteriorated Clamps

- If any deformation, damage, or deterioration is found in the clamp, do not use it and replace it with one that has no defects.

- Always inspect clamps before operation.

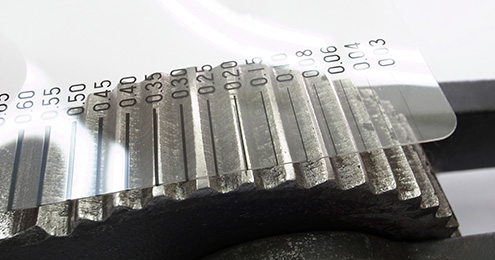

Replace Parts Early

- Using clamp parts near their wear limit is risky.

- In environments with hard loads or uniform plate thickness, replace cams (toothed plates) and swivel jaws earlier than usual.

Inspection Criteria

The following table provides references for clamp inspection.

If any listed condition is found, stop using the clamp and contact us.

Inspection Criteria Table (Excerpt)

| Inspection Location | Inspection Items | Inspection Procedure and Check Points | Usage Limits (Replace or Discard Items That Exceed the Limits) | |

|---|---|---|---|---|

| Main Body | Deformation or Cracks |

|

|

|

| Main Body Bolt | Bent Bolts |

|

||

| Main Body Pin | Bent Pins or Welding Defects |

|

||

| Lifting Shackle | Bending, Twisting, or Elongation |

|

Do not use the shackle if any of the following conditions are found: |

|

| Cam (Toothed Plate) | Wearing, Clogging, or chipping in the Teeth |

|

|

|

| Cam Pin or Lifting Shackle Pin | Bending |

|

|

|

| Wear |

|

|

||

| Swivel Jaw | Wearing, Clogging, or chips in the Teeth |

|

|

|

| Cam Pin Hole or Lifting Shackle Pin Hole | Elongation, Wear, or Deformation |

|

|

|

| Lock Device | Lock Spring | Elongation, Deformation, or Loss of Spring Tension |

|

|

| Set Bolt | Wear, Deformation, or Elongation |

|

||

| Bolt Hole | ||||

- ※This table applies only to cam-type clamps. For other products, refer to the relevant instruction manual.

Inspection Procedure

Each product has its own inspection procedure. Always follow the inspection procedure described in the instruction manual provided with the product.

For some models, the following are checklists and inspection location tables for inspection before operation. Please refer to them.

Note: These checklists and tables are updated periodically.

Importance of Regular Inspections

Please use clamps properly, and inspect them before operation and at regular intervals to ensure safety.

Inspection guidelines are provided to help prevent accidents.

Inspection Before Operation (Daily Inspection)

The user or owner must inspect before operation.

Periodic Inspection

A qualified professional should visually and functionally inspect the clamp.

If no abnormalities are found, the clamp may be labeled “Inspected.”

If necessary, disassemble the clamp and inspect the parts.

Maintain or replace parts, or send the clamp to the manufacturer (or an approved servicer) for repair.

The inspector must record and keep the inspection date and details of the inspection and any repairs.

Please refer to the separate “Replacement Criteria” table for part replacement standards.

Please Register Your Clamps

To use your clamps safely over the long term, please register each unit and have it inspected periodically until disposal.

For proper maintenance and our appropriate support, we request user registration for all our products.

Please let us know the name of your dealer and the serial number listed on the "Certificate of Inspection and Test" at export@eagleclamp.co.jp.

Replacement Parts

We offer replacement parts for your clamps.

Please check the serial number and contact your distributor or us for assistance.